Lamp Assembly

How do I build myself a lamp?

In German, the confusion is between the words “Leuchte” and “Lampe” whereby, for us English speakers, the former is the lamp bulb and the latter is the lamp. Technically speaking, we have our own problems in English because among experts (lighting designers) a “lamp” is actually what the layman calls the “light bulb”, light fixtures are called “luminaires” and the “table lamp” is called a “portable luminaire”. Since this is all a bit too much to have to learn in order to read such a short article I am going to use “light bulb” for the actual light source and “lamp” for the complete device, including base, bulb holder and shade. Plus there are lighting fixtures that are non-portable devices that you put the bulb into (like lights in a wall). That should cover it - OK?

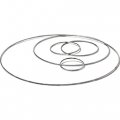

One could think that making a lamp would be simple: you just take a ring with a (washer) mount and another ring and wrap the two of them with paper and voila! – but no, that is not the case. Constructing a lamp requires exacting work and a lot of practice. It is no accident that workshops with special craftsman still exist for the purpose of making lampshades and setting them up so they function properly.

A great many types of material from our assortment can be used to make lampshades: these include Japanese paper, plastic film, self-adhesive translucent backing film, mulberry paper, silicone sheet, fabric, perforated sheet, expanded metal, copper foil, satin-finished acrylic tubes, coloured acrylic and many more.

In addition to pre-made lampshade frames, you can also go one step further and buy the basic components like the mounting (top) ring and the lower ring or just plain steel rings so you can build your lampshade from scratch. When choosing this path, a million possibilities open up to you: you can combine rings with the same diameters or with different ones whereby you can make lampshades with either parallel sides or conical shapes. In addition, you can make tube shaped shades by using three or more rings and even use rectangular rings for a further variation.

How do I construct a lamp? Four possibilities plus some processing tips

Options:

(1) The simplest method is to take a pre-made lampshade frame and wrap a nice looking, colourful paper around it whereby the paper is glued to the top and bottom rings. The paper can be of a very thin quality because the frame will be doing all the stabilizing work. One disadvantage of this method is that because the paper has not been reinforced with a film layer it will be very susceptible to tearing and the vertical struts running between the two rings can be visible, especially in the case of thin paper in a light colour.

(2) If you are constructing a pendant lamp you might consider using only one mounting ring at the top so as to allow your covering material to hang down like a curtain.

(3) In order to construct a sturdy lampshade out of two rings, a stiff material is required so that the shade will hold its shape (or you consciously forego that concern altogether so as to achieve a crumpled, Chinese lantern effect). One way to reinforce your material is to use backing film that you attach around both the top and bottom rings with glue. This will provide the stability you need even in the case of larger lamps if the thickness of your film is great enough.

(4) Because the process of gluing the rings and the paper is so difficult that you might indeed begin to think you need four hands, it is probably best to begin slowly by using a pre-made lampshade frame on your first try. It is much easier to attach your backing film to the top and bottom rings at the correct spacing if you employ vertical struts. Such vertical struts, however, do have a serious downside as compared to a construction involving only two rings: they create dark lines along the shade that can be readily seen on the exterior. For this reason many professionals remove the vertical struts at the end of the building process by cutting them off with a side-cutter – they only serve as supports during the construction of the lamp and are removed when that work is done.

A whole range of film and foils can be used for making lampshades: the most commonly used are self-adhesive, translucent plastic films because they will diffuse the light and distribute it very evenly. The thicker the plastic backing film, the more sturdy the lampshade is but at the cost of less light getting through.

Cutting the lampshade to size: the first order of business is cutting your cover material to size. In the case of square or cylindrical shapes this is comparatively easy to do because for square shapes you only need to measure and add while for cylindrical shapes you simply employ the classic formula M = d x Pi x h (diameter multiplied by Pi and that result multiplied by height) whereby “M” is the external surface. Conical shapes, on the other hand, are much more complicated but if you search in the internet using the keyword “lampshade construction” you will find all the information you need, including videos.

Gluing: if you are using a plastic film backing in combination with fabric or paper, you only need the film to fit flush to the upper and lower rings but the covering material (paper, fabric) should be long enough to wrap around the rings as a means of attachment. White glue is good enough for this job but even better is transparent, double-sided adhesive tape (for example, special double adhesive tape, transparent). In order to make the wrapping of the material easier and to assure that no folds or creases will develop during the gluing process, small triangular cuts should be made at regular intervals along the edge of the material or, alternatively, serrated glue flaps cut into the edge.

Please note: with an eye to the amount of heat discharged by your light bulb, an adequate amount of ventilation space between the bulb and the temperature sensitive or, even better, non-flammable material should be provided. The reason for this is that it is not only those now banned incandescent bulbs that produce a lot of heat but halogen and LED (somewhat less) bulbs as well. It is only the energy saving bulbs which, because of their surreal shape, produce so little heat that they can only be called warm (with the exception of the high performance version of energy saving lamps).