Aluminium sheet cut to size - order online

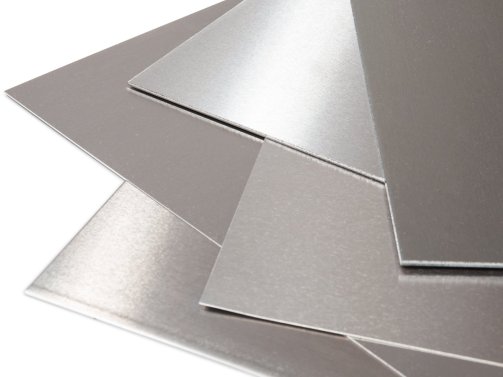

Aluminium sheets are the robust lightweights among our sheets. Whether as a cover, step protection or reflector for a light - with an aluminium blank you have a solid basis for numerous projects. Since the robust material does not rust, you can even use it outdoors.

Light and flexible - aluminium sheet blanks and their properties

No matter when, where and how aluminium is used, the focus is usually on one particular property of the material: its light weight.

Aluminium sheet blanks are extremely light and easy to form. The fact that the raw material in its pure form has only low mechanical strength is easily compensated for by alloys with other materials. Aluminium-magnesium alloys are particularly worthy of mention. But copper, manganese or zinc can also have an influence on the hardness, the heat and current conducting properties or the good corrosion resistance of the aluminium sheet blank.

Tip: As a base metal, aluminium forms a thin oxide layer on its surface. It reliably protects against weathering, but makes the aluminium look duller and more matt. If you would like an aluminium blank for your project whose surface does not change, we recommend anodised sheets such as our aluminium sheet panels, anodised. Their top layer consists of electrolytically oxidised aluminium and is particularly hard. Even powder-coated or lacquered aluminium sheet blanks are not very impressed by what happens around them. However, in contrast to the anodised variant, their protective layer is only applied and can therefore flake off under certain circumstances.

Our service: aluminium sheet cut to size

If you commission our cutting service to cut an aluminium sheet to your desired size, you will benefit in several ways.

We offer you the certainty that the end result will only have very small cutting tolerances. Even though you can cut aluminium sheets yourself with scissors, a cutter or a saw, depending on their thickness, one thing is indispensable: you have to work very precisely. Mistakes can hardly be repaired, the material deforms relatively easily and in case of doubt, you are better off with our expertise and the well-equipped Modulor workshop.

Furthermore, ordering aluminium cuttings online offers you added convenience. You can simply receive the finished sheets at your home.

Important: When cutting aluminium sheet, note that often only one side of the sheet is equipped with a protective film. The other side may be scratched due to processing and transport.

Smooth or corrugated - which sheet metal would you like?

Do you want to add water surfaces or metal facades to your model buildings? Do your steps need a step protector or are you planning to build an enclosure or an enclosure cover? Thanks to their diversity, aluminium sheet blanks offer you uncomplicated solutions. The material is more robust and torsion-resistant than acrylic glass, for example, and is easier to drill than steel.

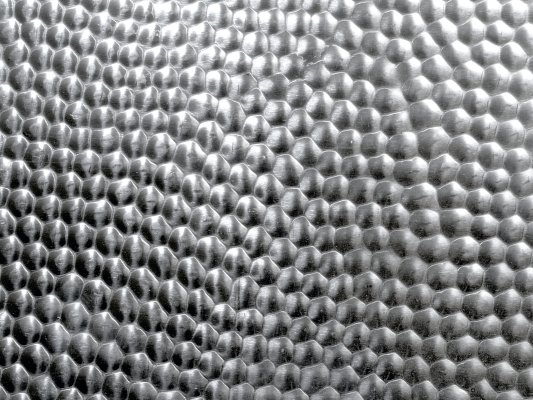

In our range you will not only find smooth aluminium sheets in various thicknesses and qualities. If you are looking for an aluminium blank to be used as a reflector, a hammered sheet, for example, is convincing. It offers good light diffusion and is less sensitive than its smooth relatives. Small dents and damage are simply less visually noticeable.

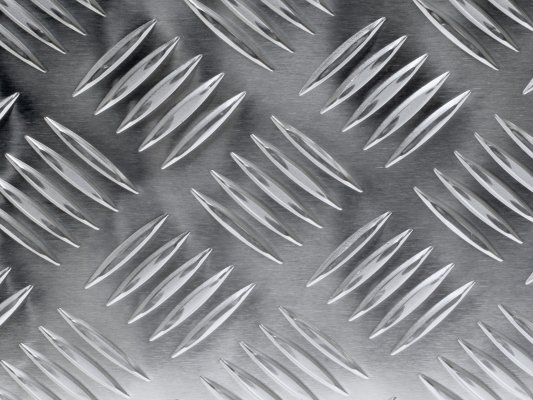

So-called caterpillar or checker plate blanks also score with structure. They are equipped with diagonally offset ribs, often arranged as a duet or quintet, which are embossed into the sheet with rollers. The small elevations increase slip resistance, especially in wet conditions, and provide steps, ramps and the like with an extra portion of slip resistance.

Practical: You can easily see whether the sheet metal of your choice is available as a cut to size by the small saw blade in the corner of the product image.

Interesting: aluminium sheets do not only appear solo in our shop. In combination with a polyethylene core, you can also find them as Dibond sheets in our cut-to-size range.

Screwing, welding, soldering - get your aluminium blank into shape

Screwing, welding, soldering - get your aluminium blank into shape

The good news first: You can screw, bend or fold your aluminium sheet blank. Be sure to take into account the high springback of the sheet and work at right angles to the rolling direction if possible. This prevents the material from tearing.

For cutting work it is important how hard the alloy is that you want to process. If you have a very soft material in front of you, it can smear heavily when you drill, mill or grind. Aluminium dust is also flammable. It is advisable to use a wet process and to remove sources of ignition in the immediate vicinity.

If you want to process your aluminium sheet blank by welding or soldering, remember the oxidative properties of the material. While the melting point of aluminium is around 660 °C, the oxide layer needs a whole 2000 °C before it liquefies. It may therefore be necessary to remove it either mechanically or chemically before you can proceed to the next step.

It may also be advisable to remove the aluminium oxide with an abrasive fleece before gluing with epoxy or power adhesive or painting your aluminium blank.

Practical tip: For easy bonding of the blanks, you can also use mounting tapes such as Tesa mounting tape Outdoor, Orabond 1811 mounting tape for mirrors or acrylate mounting tape, adhesive on both sides.

Metal meets metal - keyword contact corrosion: You want to combine different metals for your project? You should consider the following when planning your project: Depending on the inherent electrical potential, the presence of an electrolytic conductor and a different corrosion resistance of the materials, an electrochemical reaction can occur. As a result, one of the two metals begins to corrode.

To avoid this contact corrosion, it can be useful to:

- shield the different metals from each other,

- choose the materials in such a way that contact corrosion does not occur,

- make sure that no corrosion medium is present.

Background knowledge! What is aluminium?

Aluminium foil, bicycle frames, cooking pots and beverage cans: as the second most important material, aluminium is omnipresent in everyday life, right behind steel. But hand on heart - can you answer the question "What is aluminium?" just off the top of your head?

Aluminium - or aluminium for short - is a light metal that is the third most common element in the earth's atmosphere after oxygen and silicon. It does not occur in nature in its pure form, but mostly as a compound in ores. The most important raw material for its extraction is bauxite. The production of aluminium is extremely energy-intensive. The environmental impact of ore mining and waste disposal cannot be ignored either.

Aluminium and aluminium sheet blanks have an almost unlimited recyclability. Secondary aluminium hardly shows any qualitative differences compared to primary aluminium. In addition, the recycling process requires only a fraction of the energy of primary extraction. In this context, however, it is important that the various alloys are collected and reprocessed according to type. Otherwise, so-called downcycling occurs and the valuable material loses quality.

It is interesting to note that slightly more than 50% of the aluminium produced in Germany is secondary aluminium. It can be assumed that around 75% of the aluminium ever produced is still in use worldwide.

Our sheet metal blanks

Is an aluminium sheet blank, with all its advantages, not the material you have in mind for your project? Then our steel, copper or brass sheet blanks might be more to your liking.