Cutting Service

Metal and sheet metal cut to size

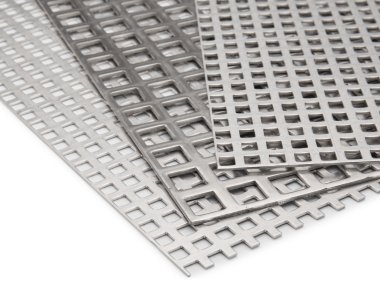

Perforated sheet cut to size

If light or air permeability is required, you can count on our perforated sheet cuttings. With round, square and cross perforations, they provide visual variety.

Sheet steel cut to size

Create a magnetic wall for your work area or add a high-quality splash guard to your kitchen. In our cut-to-size section you will find robust and durable steel sheets as well as their harder stainless steel relatives for your projects.

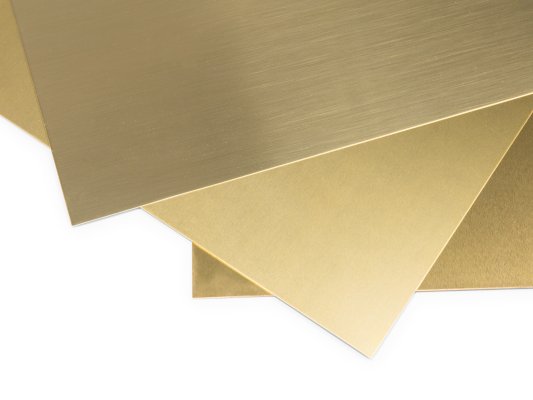

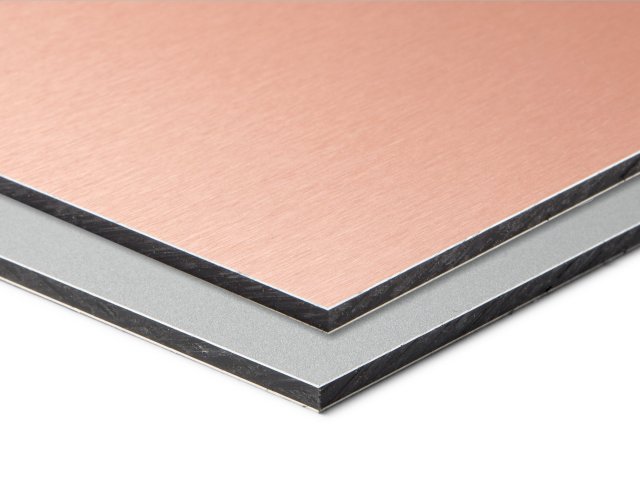

Copper sheet cuttings

May we introduce: the aesthetes of our cut-to-size products - copper sheets. They skilfully combine a warm colour tone, an incomparable patina and weather-resistant as well as antibacterial properties.

Blanks in the Berlin shop

Would you like to take a closer look at the different materials? Then come and see us! Our cutting service is not only available online, but also in our shop. At Moritzplatz in Berlin, you can have sheets and plates cut to your desired size.

We cut paper, cardboard, carton, rods and tubes exclusively for you on site. You also have the option of ordering drilling and bending. We have summarised all the important information for you on our page for individual material processing.