Synthetic sheets cut to size: individual and true to size

Lightweight, resilient, durable and easy to clean - synthetic sheets offer numerous advantages when it comes to implementing creative ideas. Regardless of whether you want to design displays for an exhibition, create a room divider or design shop fittings: With an HPL panel made to measure or an Alu-DIBOND® cut, you can easily realise your plans. You decide which polymer you want and we cut the material of your choice to suit you and your project.

Our contribution to your project: a synthetic sheet cut-out

Would you like to order a cut-to-size synthetic panel in white or does your exhibition stand require a robust composite panel? We can cut a wide variety of materials to the size your idea requires. You can safely disregard the question "How do I cut synthetic sheets? You need neither a saw nor specific expertise to put your plan into practice. Instead, you can find the exact conditions for cutting plastic sheets on our individualization page. We will give you a brief overview of the most important materials and their characteristics right here.

Durable and robust: hard synthetic sheets

The term "hard synthetic sheets" covers a wide range of materials with one thing in common: they all have a high degree of rigidity and hardness.

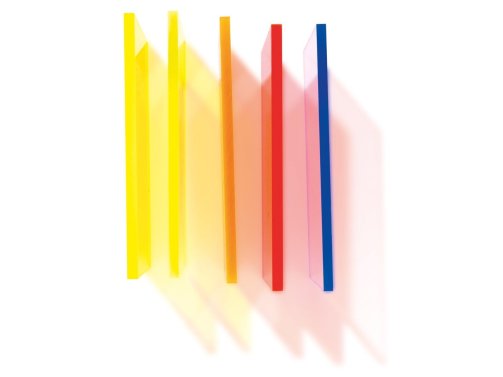

Your synthetic sheet cut - from transparent to weatherproof

We have dedicated separate chapters to the two best-known representatives, acrylic and PLEXIGLAS®. If you are looking for a lightweight, break-resistant and weatherproof material, they are a suitable solution. But our PVC sheets made to measure and polystyrene versions can also be an alternative for your project. Both qualities are also light and easy to work with. They hardly absorb any water and can be used in wet areas without any problems. While polystyrene is not weatherproof and UV-stable, PVC sheet blanks offer you weatherproof properties. You can easily install them outdoors.

An HPL panel from the blank - durable and robust

HPL board blanks, so-called high pressure laminates, consist of paper soaked in synthetic resin and pressed under high pressure. They are extremely impact and shock resistant as well as insensitive to scratches, moisture and temperature fluctuations. Thanks to their closed surface, plastic panel blanks in HPL quality are not only to be found as a durable building material indoors: The robust panels are even convincing as a house façade.

Whether it's an outdoor toy box or a table top for our M frame: the edges of a plastic sheet blank made of HPL are so sharp that it is necessary to break, edge or sand them. You can work the material with carbide-tipped machines that are also suitable for wood. To join the individual components together, we recommend that you screw the elements together.

Hard foam sheets - the light and dimensionally stable plastic blank

Rigid foam sheets are made of foamed synthetics. They are extremely dimensionally stable and have high strength despite their minimal weight. Their thermal conductivity is low, so you can use them as insulation material, among other things. Furthermore, they are usually resistant to moisture. But be careful: In this context, it is important to note that a plastic sheet cut from rigid foam only allows a low moisture exchange.

FOREX® - the visual communication talent

FOREX® is one of the best-known representatives of rigid foam sheet. Developed in Switzerland in the 1980s, the sheet is made of foamed PVC. It has a uniform, closed cell structure and a silky matt surface. A synthetic sheet cut from FOREX® is easy to print, paint and varnish. It has lightfast, impact-resistant and stable properties and insulates against heat, cold and sound. Since it is also weather and moisture resistant, you can use the plastic blank outdoors and in wet rooms without any problems. In addition, FOREX® sheets are flame-retardant and self-extinguishing as soon as the fire source is extinguished.

FOREX® at Modulor

In our range you will find the following variants of the hard foam board: FOREX®classic is extremely robust and has a surface that is ideal for laminating and printing. FOREX®color adds more colour to your plastic sheet cuttings. The product family, which is available in various shades and is designed for indoor use, consists of a material that is uniformly coloured throughout.

Both versions are ideal for exhibitions, stage sets or window displays. You can use them in architectural model making, as travelling panelling or room dividers. In combination with self-adhesive film, they form a good basis for signs. The processing possibilities of a plastic sheet cut from FOREX® are comparable to wood. You can nail, screw, rivet, glue and shape the practical material.

Composite panels: Plastic blanks in layered design

Composite panels are characterised by their sandwich design. Since their synthetic core is embedded between two cover layers, they offer high flexural strength and good flatness. Their low weight makes transport and installation of a synthetic sheet blank uncomplicated.

DIBOND® - the elegant lightweight for signs and prints

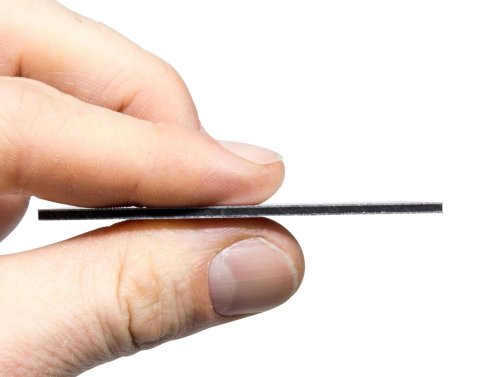

Probably the best-known variant, DIBOND® is a lightweight composite panel whose polyethylene core is framed by two 0.3 mm thick aluminium sheets. The material has a good surface finish. It is resistant to bending, weathering and UV radiation and has excellent machinability. Since DIBOND® only conducts heat to a limited extent, a plastic sheet blank of this quality always keeps its shape perfectly. It neither tends to deform nor to warp.

You can saw, drill, mill, punch, print, laminate and paint Alu-DIBOND® blanks depending on the desired use. As a carrier material for screen and digital prints, they are an ideal presentation material.

In our cut-to-size section, you will find DIBOND® as a classic metallic variant, as a plastic sheet in white and as a cut-to-size sheet with a mirrored surface.

Stadurlon: the plastic sheet blank with extra power

A plastic sheet blank made of Stadur Viscom Sign Easyprint scores as a PVC-free FOREX® alternative and offers comparable properties to DIBOND®: it is light, insensitive to moisture and optimally suited for large-area signs and displays. Its core is made of polystyrene, the cover surfaces consist of the PVC-free high-performance plastic Stadurlon. It is UV-resistant, pressure-resistant and scratch-resistant. You can bend it several times before it gives way and breaks. If you want to laminate photos or prints, you can also find the self-adhesive version Stadur Viscom Fix in our range.

Cut to size in Berlin

Have our plastic sheets made you curious? Then come and visit us in our shop at Moritzplatz. Here you can see for yourself which materials we can cut to your desired size. All important information about our cutting in Berlin can be found on our individualization page.