PLEXIGLAS® cut to size

Framing pictures, building lamps, creating advertising signs and light boxes ... The list of your projects can be long and varied. PLEXIGLAS® cut to size makes it easy and convenient to implement.

What is PLEXIGLAS®?

The term PLEXIGLAS® stands for nothing other than the trademarked acrylic glass of the Röhm company. Like other acrylic glasses, it is made of the thermoplastic polymethyl acrylate or PMMA for short.

The brand name goes back to the plastic resins and solutions of the Röhm & Haas company known as PLEXIGUM. Since its introduction in 1933, it has become synonymous with acrylic glasses from a wide range of manufacturers.

What is the difference between PLEXIGLAS® and acrylic glass?

A look at our acrylic glass cut-out makes it clear: visually, the branded product and its numerous competitors are hardly distinguishable from each other. Those looking for a difference between PLEXIGLAS® and acrylic glass will find it primarily in the area of the guarantee. Depending on the plexiglass variant, Röhm guarantees the material's UV and weather resistance for up to 30 years. A convincing practical test was carried out, for example, on the Olympic Stadium in Munich, which went into operation in 1972.

Fun fact: If you are looking for a PLEXIGLAS® cut on the American market, you will find the brand acrylic glass from Röhm under the name ACRYLITE®.

From unbreakable to UV-resistant - these are the properties of PLEXIGLAS®

This practical plastic scores with its light and break-resistant properties. It is extremely light-transmitting and also offers good UV protection. This protection is not applied to the product from the outside, but is integrated directly into the acrylic sheet (Naturally UV-STABLE technology). The molecules are UV-stable and do not yellow even under the influence of the sun. In combination with a service temperature of -40 to 70 °C, there is nothing to prevent your PLEXIGLAS® sheet from being used outdoors.

Good to know: The UV protection of the acrylic glass is a convincing positive extra. If, for example, you want to frame your favourite pictures with a cut-out, you can be pleased that the colours will remain intact for a long time. PLEXIGLAS® Gallery UV 100 even meets the requirements of galleries and museums. It filters out rays in the UV-A range almost completely.

PLEXIGLAS® cutting: online and convenient

In our cutting department, we cut PLEXIGLAS® to the individual size you need. You can conveniently order the sheets online and have them delivered to your home. Since Plexi is both lightweight and unbreakable, it offers ideal conditions for shipping.

What other arguments speak in favour of using our service to realise your ideas? Quite simple:

From a certain sheet thickness, carbide-tipped tools are indispensable for a clean PLEXIGLAS® cut. Acrylic sheets are under tension and tend to break out. In addition, PLEXIGLAS® melts during cutting if it gets too hot from a saw blade running too fast. The keyword is: thermoplastic. Extruded PLEXIGLAS® XT, which is manufactured by drawing liquefied granules into shape, is more sensitive to heat than cast PLEXIGLAS® GS. We provide you with both our expertise and our equipment to cut your PLEXIGLAS® to size.

Note: If you want to process the plastic after cutting, it is easier with the cast version. If you enjoy handicrafts and follow our practical tips, you can e.g. score break, mill, drill, glue, shape, etc.

Important: Our PLEXIGLAS® cuttings arrive with rough edges. You can smooth the cut surfaces with a scraper and wet sandpaper. A polishing cloth and polishing paste literally give them the finishing touch.

Whether luminaires or privacy screens - PLEXIGLAS® blanks score as all-rounders

Acrylic glass from Röhm is available in numerous variants. With a rough classification, we offer you a brief overview of which quality you can take a closer look at for your plans.

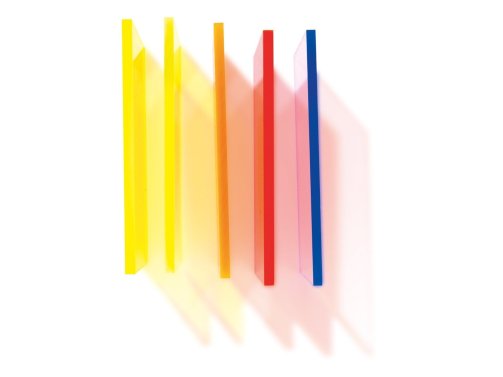

Colourful plexi for colourful ideas

PLEXIGLAS® is absolutely colourless in its pure form. It is ideal for colouring and can shine in numerous shades. If you consider its decorative appearance in combination with the light-conducting properties of the material, one possible use is already obvious: have PLEXIGLAS® cut to size and create colourful light objects and luminaires.

Is your budget limited? Perhaps transparent acrylic XT in combination with a translucent or transparent colour film is an alternative for you.

The robust cut: satin Plexi

If you are looking for translucent but opaque qualities, a satin-finish PLEXIGLAS® sheet is a good choice. Its sandblasted surface has a matt, velvety look. It is scratch-resistant and resistant to fingerprints. Depending on whether one side of the sheet is satinized or the front and back sides are treated, we speak of Satinice SC or Satinice DC. Both versions convince with good light diffusion. You can use them for illuminated objects, partition walls, furniture doors and numerous other projects. Even use in the bathroom or garden is possible thanks to the material's moisture- and weather-resistant properties.

Practical tips: Our PLEXIGLAS® Satinice SC, one-sided satin, coloured sets fresh accents with its modern coloured sheet. For a classic privacy screen, PLEXIGLAS® in milky quality can also be cut to size as an alternative to satin acrylic.

Anti-reflective plexi for art and co.

Acrylic glass qualities that are roughened on one side and minimise light reflections are the ideal basis for framing pictures. If you choose our PLEXIGLAS® XT sheet transparent, antireflective, for example, you can optimally block out your surroundings and lose yourself completely in a work of art.

Important: Make sure that the glossy side of the Plexi sheet lies directly on the poster, photo or artwork. Only then is the acrylic transparent.

What else is there to discover?

You find it practical that we cut PLEXIGLAS® to size? Our team can also cut wood and sheet metal to your desired size. Get to know our cutting service and discover the numerous possibilities for your ideas.

Thanks to the small saw blade on the product image of our sheets, you can see at a glance whether the article is available as a cut to size. All detailed information on minimum dimensions, prices, cutting tolerances, etc. are listed in detail on our page on the subject of individual material processing.