The aluminum composite panel Etalbond is characterized - like the better-known material Dibond - by low weight, high flexural strength, solid flatness and UV resistance. In contrast to cheaper Dibond alternatives, the protective film can always be removed consistently well. In addition, the panel can be printed on consistently well and the aluminum is equally strong at every point, which is a major advantage, especially for further processing such as milling.

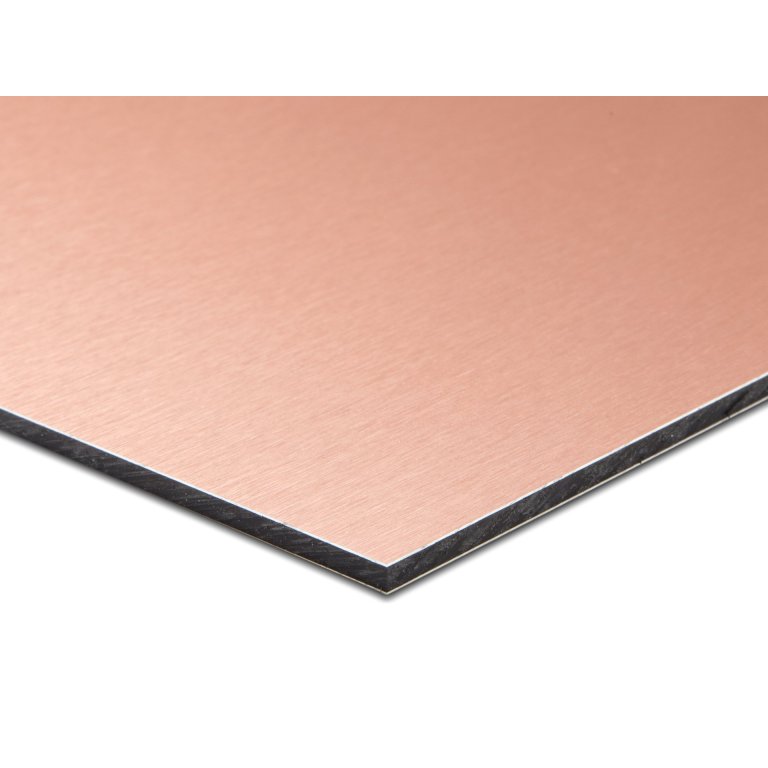

High dimensional stability, precise edges and a robust surface predestine the easy-to-process sheet for the construction of trade show booths, displays and window dressings. In the copper-colored, brushed surface variant, Etalbond cuts a particularly good figure as a decorative room divider, furniture or wall cladding.

By folding and bending using the so-called "milled edge technique", in which a v-shaped groove is milled into the back and part of the LDPE core and the aluminum cover sheet of the front are left in place, a wide variety of three-dimensional shapes can be realized.

Of course, Etalbond is also suitable for the production of indoor and outdoor signs. The high-quality polyester coating of the aluminum cover sheet ensures printability using digital and screen printing processes, can be bonded with adhesive films and offers excellent corrosion and UV protection when used outdoors.

Circular saws, panel saws and impact shears are suitable for cutting Etalbond. Curved cuts can be made with a jigsaw or scroll saw, and in the professional sector with a CNC router.

Holes are best drilled with twist drills for metal or plastic. A high speed at a low feed rate ensures that the chips are removed cleanly. A sheet metal punching machine can be used to punch holes with a minimum diameter of 4 mm.

Etalbond is joined and fastened with stainless steel or aluminum rivets or screws. Metal adhesives for aluminum (e.g. the epoxy two-component adhesives) or strong double-sided adhesive tapes are suitable for bonding. Velcro tapes such as Dual Lock are also suitable for resealable joints. An ideal adhesive for attaching angles for hanging on the back, for example, is the assembly adhesive Weicon Flex + Bond.

This article is available cut to size. Choose your desired size! You can find more information under customization.