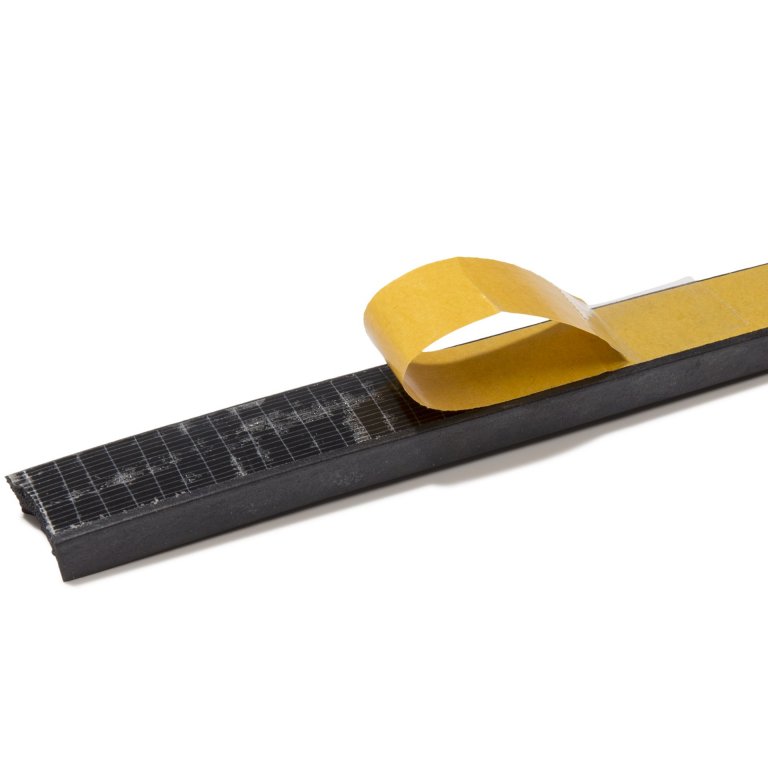

These foam rubber rectangular strips are made from EPDM caoutchouc, which is a lightweight, highly elastic synthetic rubber. The core of this material is porous like a sponge, has an open-celled structure and a cell-free, smooth and closed outer skin (it is this property that distinguished “real” foam rubber from the “phony” knock-offs), The outstanding features of foam rubber include a high degree of UV resistance, weather resistance, temperature resistance from about –30 to about 110 °C and, last but not least, it is waterproof.

The classic use of foam rubber is to process it into cords and profiles for sealing purposes or for vibration or sound insulation applications in the automobile and electronics industries. In other cases, it can be used as a versatile decoration material and/or advantage can be taken of the high degree of frictional resistance of its surface in other applications (walkways, etc.).

We offer our sealing strips in a group that includes both the foam rubber and cellular rubber versions. Why? Because the basic raw material is the same, their adhesive and material properties are very similar and their fields of application are almost identical as well. There are, of course, differences in their physical dimensions and, most noticeably, in their surfaces; i.e. that of foam rubber is smooth and closed and that of cellular rubber is open-celled (only on the surface!). The frictional resistance of foam rubber in relation to most materials is therefore much higher: if you need a foam rubber adhesive strip that has anti-slip characteristics, standard foam rubber should be your choice.