| Article No. |

|---|

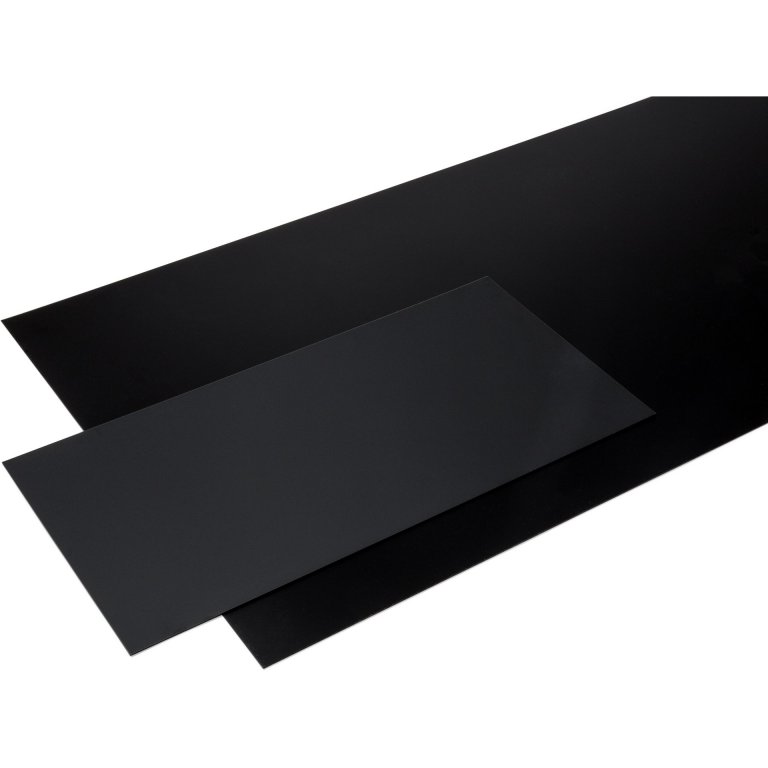

impact-resistant, black

Polystyrene is the absolute classic model making material and with good reason: it is easy to cut, glues well, and lends itself to deformation. Models made from polystyrene should definitely be subsequently coated with varnish because otherwise they will tend to attract dust. In addition, a varnished model will have considerably more plasticity.

Straight or curved sheets can be made by means of scoring with a cutter or a scoring tool and subsequently breaking it along those lines. Good results will be achieved on sheets with thicknesses up to 2 mm using this method. In the case of thicker polystyrene it is advisable to break it along a straight edge in order to attain a straight clean cut. If you require that the cut surface be smooth it is better to use a circular saw. Circular saw blades produce the best results if the teeth are unset, conically relief-ground and have a low cutting angle (in the case of HSS blades, between 5 and 8 degrees; in the case of carbide blades, from 0 to 5 degrees). Round or more complicated shapes can be made by using a fret saw, scroll saw or a jig saw.

For the architectural model maker it is fairly easy to produce a layered topographic model using polystyrene sheets: each layer of sheet is covered completely with thin Double-Sided Adhesive Film, transfer glue or self-Adhesive Films and stacked one upon the other. When finished, the resulting visible layer lines should be brushed with a solvent, for example Dichloromethane, whereby the polystyrene “dissolves” into a uniform looking surface.

Small openings can be cut into facades when the PS sheets are no thicker than 0.75 mm. In order to produce a sense of depth, the sheets can be glued to solid objects made out of PS foam, acrylic or wood. Cut-outs from thicker sheets must be sawed or scored and broken through.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Black polystyrene sheets do not have a protective film and can therefore end up being lightly scratched during the delivery process. Polystyrene should not be used outdoors because it is not UV resistant.

| Article No. |

|---|

impact-resistant, black

Polystyrene is the absolute classic model making material and with good reason: it is easy to cut, glues well, and lends itself to deformation. Models made from polystyrene should definitely be subsequently coated with varnish because otherwise they will tend to attract dust. In addition, a varnished model will have considerably more plasticity.

Straight or curved sheets can be made by means of scoring with a cutter or a scoring tool and subsequently breaking it along those lines. Good results will be achieved on sheets with thicknesses up to 2 mm using this method. In the case of thicker polystyrene it is advisable to break it along a straight edge in order to attain a straight clean cut. If you require that the cut surface be smooth it is better to use a circular saw. Circular saw blades produce the best results if the teeth are unset, conically relief-ground and have a low cutting angle (in the case of HSS blades, between 5 and 8 degrees; in the case of carbide blades, from 0 to 5 degrees). Round or more complicated shapes can be made by using a fret saw, scroll saw or a jig saw.

For the architectural model maker it is fairly easy to produce a layered topographic model using polystyrene sheets: each layer of sheet is covered completely with thin Double-Sided Adhesive Film, transfer glue or self-Adhesive Films and stacked one upon the other. When finished, the resulting visible layer lines should be brushed with a solvent, for example Dichloromethane, whereby the polystyrene “dissolves” into a uniform looking surface.

Small openings can be cut into facades when the PS sheets are no thicker than 0.75 mm. In order to produce a sense of depth, the sheets can be glued to solid objects made out of PS foam, acrylic or wood. Cut-outs from thicker sheets must be sawed or scored and broken through.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Black polystyrene sheets do not have a protective film and can therefore end up being lightly scratched during the delivery process. Polystyrene should not be used outdoors because it is not UV resistant.