Melamine Table Top

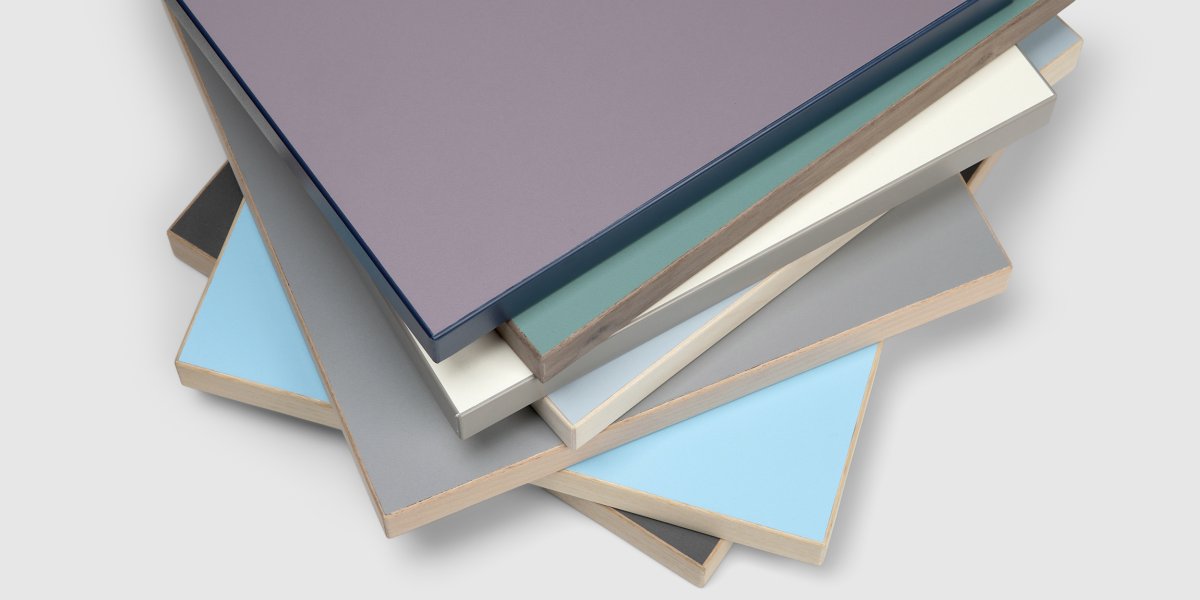

Our table tops with melamine resin coating are the classic option for any table. Whether for use at the desk or for cosy meals in the kitchen - melamine tops are inexpensive and durable. Their chipboard core also makes them resource-friendly. But you don't have to do without style. You can put together the table top of your choice yourself from the numerous colour and edge variants.

- Classic worktop

- Good value

- Resistant

- Resource-saving chipboard core

- 19 mm or 25 mm thick

- Maximum size 275 cm x 140 cm

More than standard: the melamine worktop

When we say "proven standard" for our melamine resin table tops, we mean anything but mediocrity! Our melamine-coated table tops are durable and robust and therefore set standards. The table tops are industrially manufactured from high-quality materials. At the core of the table top is a certified and therefore pollutant-free chipboard. The scratch-resistant melamine resin coating in the colour of your choice ensures durability.

All this together makes a melamine-coated table top an all-rounder. Whether for long office working days in front of large or small screens, for kitchen or break tables or as an enduring companion during childhood and adolescence: The melamine desk top can withstand a lot. Of course, you can have your melamine table top made to measure. Everything is possible up to a size of 275 cm x 140 cm.

Please note, however, that the melamine board only has one chocolate side. We only guarantee you at least one flawless A-side. Slight impairments to the surface quality of the B-side cannot be ruled out and are not grounds for complaint.

How to make your melamine table top unique

In addition to the worktop colour, you can set accents on your melamine worktop with edge banding and worktop thickness. The edge banding is a coating on the edge of the table. It conceals the open chipboard that forms the base of the melamine worktop. At 2 millimetres thick, our edgebands are much more robust than on conventional pieces of furniture such as cupboard doors or shelves. In contrast to our linoleum table tops, the thickness of the edge is also visible from above and below. It therefore not only covers the side edges, but also visually frames the top and bottom of the worktop. You can choose between edge banding made of real wood or plastic.

Plastic edging

The ABS plastic edging makes every melamine resin-coated table top an eye-catcher. All combinations that our colour palette offers are possible - from monochrome to contrasting. For example, you can match the colour of the top and edges to the colours of your company logo or choose tone-on-tone edging and table top for a monochrome look. There are 19 different colours to choose from.

The colour of a melamine table top can also be combined with an edge band made of untreated real wood. A white melamine table top looks classic and cosy with a real wood edging. You can choose from eight different wood edgings, from maple to walnut, to match your wooden furniture at home.

Two panel thicknesses

Our melamine panels go through thick and thin. There is a choice of thin 19 mm and thick 25 mm boards. The thinner version is primarily suitable for smaller tables such as side tables, living room tables or plant stools. For use as a desk or worktop, we recommend a table frame with supporting frames for the thinner tops. This ensures that the melamine table top does not sag or warp. The frames from our M, T and Y series are suitable for this.

With the 25 mm thick melamine table tops, you can also safely equip larger writing and conference tables. For reasons of stability, we only recommend a table frame with supporting frames for cantilever lengths of around 160 cm.

Practical cable grommets

Nobody needs tangled cables! With a cable aperture in your melamine tabletop, you can banish your device, charging and lamp cables under the table. This not only leaves you with more space, but also gives your table a (potentially) tidy overall appearance.

You can also choose from different variations of the cable aperture to suit your own taste and position it anywhere on the worktop. The cable apertures are available in matt black, matt silver and stainless steel - each with flexible black plastic bristles so that nothing slips through. Thanks to the locking mechanism in the lid, the cable aperture sits firmly in the melamine table top - even if the cables move.

How to keep your melamine table top beautiful

The melamine coating of your table is robust and scratch-resistant. Nevertheless, we recommend avoiding certain cleaning agents and tools. The best way to clean your melamine table top is with a damp cloth and gentle cleaning agents. Scratchy sponges and pot cleaners, on the other hand, can leave clear marks and damage the surface of the melamine table top. So keep your hands off them! The same applies to cleaning an edge banding made of ABS plastic.

Dirt can also be removed from edge banding made of real wood with a damp cloth. If the wood fibres of the untreated real wood have raised after contact with water, you can carefully sand the dried edgeband with very fine sandpaper. This will give you a smooth edge again. You can permanently seal a real wood edge band with worktop oil from Biofarben. It contains natural oils and waxes, is transparent and makes the table edge water-repellent and resistant to stains.

Discover all table tops from Modulor

MelaminE is not the right surface material for your requirements? Then take a look at our other table tops. With our noble linoleum, hard-wearing HPL or classic solid wood table tops, everyone will find the right table top for them. And they all have one thing in common: they can be configured in colour, shape and size to suit your requirements.